Long guide handle makes steering and turning easier

- The length of the guide handle was chosen to provide optimum leverage. This makes turning and maneuvering particularly easy.

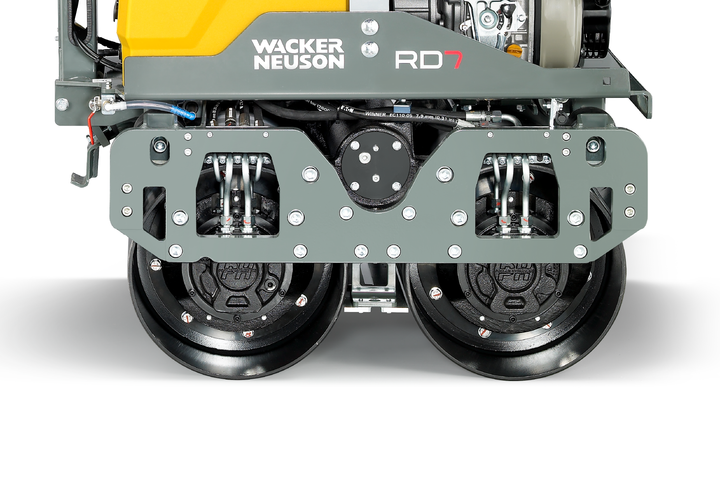

RD7

The RD7 walk-behind dual-vibration roller delivers excellent performance in both soil and asphalt compaction - thanks to the optimally integrated frequency and two vibration stages. As a result, the roller is characterized by its ergonomically arranged operator controls, such as, the engine rpm adjuster attached to the center pole. Even the easy, tool-free access to all service points makes the RD7 a simple and economical solution for every construction site.

Wacker Neuson China Ltd.

No.1688 Xinkai Road

Pinghu Economic Development Zone

Pinghu City

Zhejiang Province

P.R China.

Phone: +86 0573 - 85820666

Fax: +86 0573 - 85820555

E-mail: china@wackerneuson.com